Main boiler SH support tube renewal

- Source:

- Time of issue:2023-04-13 09:46

- Views:

(Summary description)

Main boiler SH support tube renewal

(Summary description)

- Categories:Company News

- Author:Alex Zhang

- Source:

- Time of issue:2023-04-13 09:46

- Views:

1.Main boiler details:

Maker: MITSUBISHI MARINE BOILER CO.,LTD

Type: MB

Design pressure: 7.65MPa

Class: LR

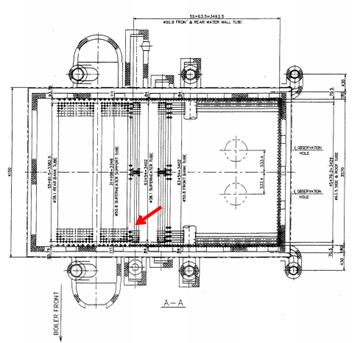

2. Boiler sketch

3. No.1 main boiler status statement

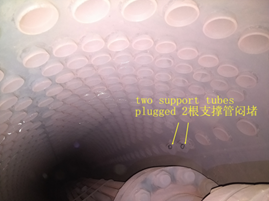

3.1 2pcs support tubes plugged in STB side main boiler.

Two support tubes plugged in STB side main boiler

4. Repair scope

Replacement of the 2pcs plugged support tubes

Note: Due to the limited space, for the aim of replacement of 2pcs plugged support tubes, will sacrifice successive four sets super heater coil elements as access (all the 4 sets located in PASS1, that is No.9, No.10, No.11&No.12 panels counted from front), shown as the following sketch marked in the red square box.

5. Repaired on site

The replacement of the 4panels tube coil in the pass1 of the superheater and 2pcs plugged support tubes

5.1 Isolate and drain the main boiler.

5.2 Remove the smoke box under the super heater water headers after remove the cladding and insulation sheet.

5.3 Remove the desuperheater/control desuperheater in water/steam drum.

5.4 Remove the superheater corridor refractory and its support plate in way of repair. Crop off the 4 sets successive coil elements(No.9, No.10, No.11 &No.12 coil in PASS 1 counted from front side)and the 2pcs plugged support tubes out of boiler.

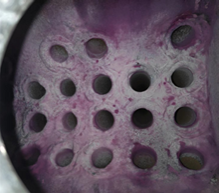

5.5 Remove the tube stubs out of superheater headers by milling.

5.6 Remove the tube stubs from water drum and steam drum for the support tubes.

5.7 Dye check the tube holes to make sure defect free after grinding.

5.8 Install and fix the new coils in position (the tube end is 2~4mm above the tube hole), attention to be paid that the support should be in place.

5.9 Expand the tube ends of new support tubes.

5.10 Heat the super heater headers

5.11 Weld the tube ends to super heater headers by coded welders.

Weld the tube ends to water header after preheat

5.12 Dye check the new weld to make sure defect free after cool down and polish.

5.13 Hydraulic test the boiler witnessed by attendant surveyor and client.

5.14 Build up new superheater corridor refractory.

5.15 Refit the desuperheater in position.

5.16 Box up the boiler in order.

LISTEN TO THE VOICE OF EVERY CUSTOMER

+86-21-50808750

+86-21-50808750 sale@boilerman-service.com

sale@boilerman-service.com Message

Message